FOR BIELLA SHRUNK PROCESS, EACH NEW PROJECT IS BORN AND DEVELOPED AS A STORY THAT VALUES THE CLIENT'S NEEDS; EXPERIENCE, PROFESSIONALISM, AND KNOW-HOW MERGE WITH THE AIM OF OFFERING VERSATILE AND SUSTAINABLE PROCESSES.

Drago Spa first tests then confirms the potential of the new Kinetika washing process

April 2017

The programme of continuing investiment and technological innovation by Drago Lanificio in Biella, is characterized by the wish to optimize the environmental impact of its production sites... we are amazed by the total absence of tension in the fabric...moreover the textiles washed with Kinetika present a feel which surprised us...

Lanificio Ferla Spa and Ti.F.A.S. Spa: the new Kinetika continuous washing system

June 2021

Two leading companies, Lanificio Egidio Ferla Spa e Ti.F.A.S. Spa, have made animportant investiment by equipping themselves with the new Kinetika continuous washing system from Biella Shrunk Process...

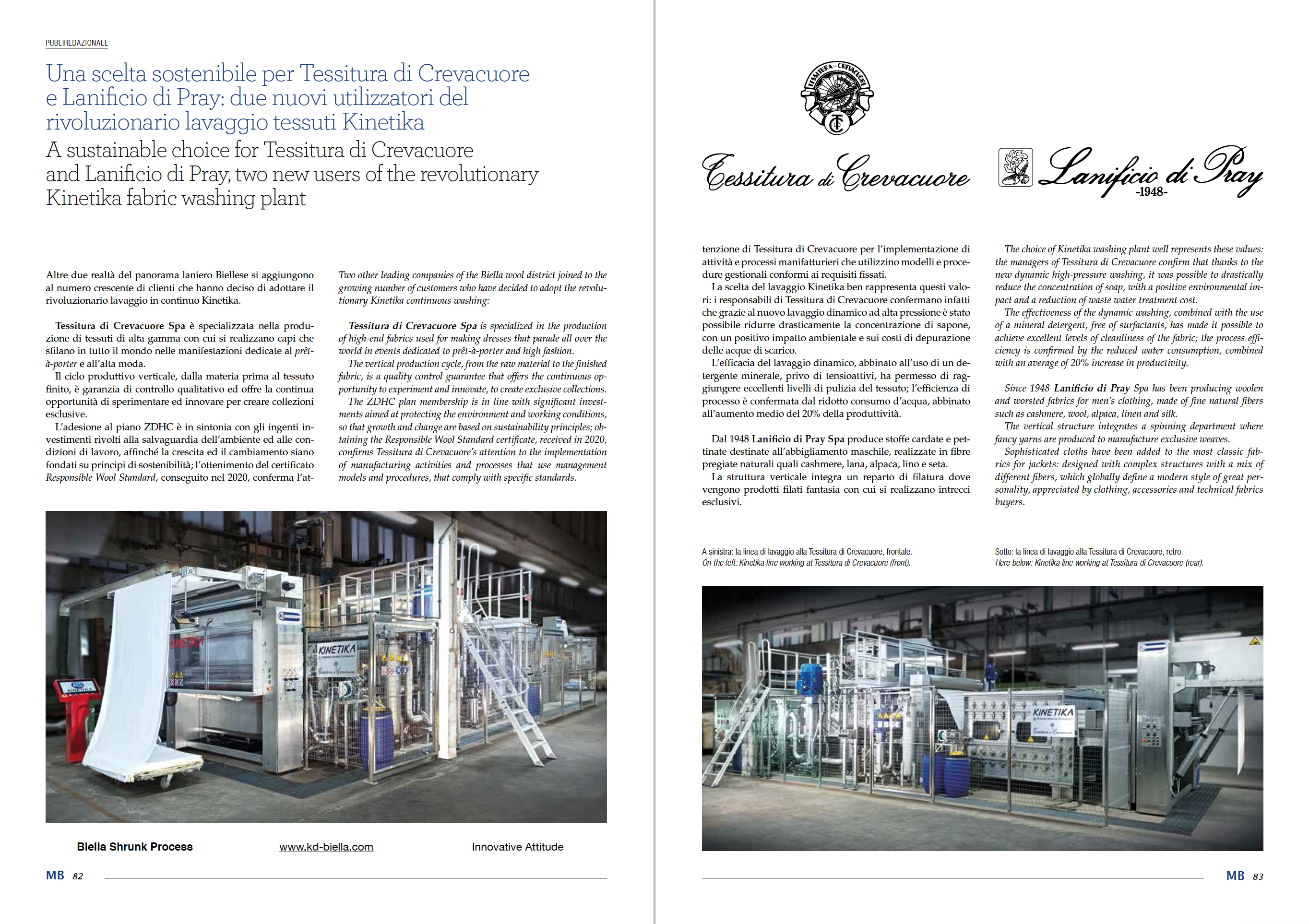

A sustainable choice for Tessitura di Crevacuore and Lanificio di Pray, two new users of the revolutionary Kinetika fabric washing plant

June 2021

Two other leading companies of the Biella wool district joined to the growing number of customers who have decided to adopt the revolutionary Kinetika continuous washing: Tessitura di Crevacuore Spa is specialized in the production of high-end fabrics and Lanificio di Pray Spa has been producing woolen and worsted fabrics...To support and optimize the production of such complex and creative collections it is necessary to rely on a production versatility granted by Kinetika dynamic washing principle...

Innovative washing process, Miko chooses Kinetika

June 2022

Miko srl was founded in 1997 by establishing its headquarters in Gorizia...the dyed fabric is first treated with the new Kinetika which, thanks to the particular patented high-pressure spraying technique, effectively extracts color residues and removes excess products used in previous processing phases...

Kinetika washing module - water recycling: every drop counts

June 2023

Water recycling is one of the strengths of the new Kinetika continuous fabric washing unit, thanks to the filtration and fluid recirculation technique, it is possible to achieve excellent cleaning results while using less clean water...is sized to reach a pressure of 10 bar with which up to 140,000 liters of fluid per hour are recirculated...

Iride srl has chosen Nanomix Evo

December 2023

Iride srl is a company founded in 2013 and operates in the field of fine fabrics dyeing and finishing, which has made an extensive program of investment in technological innovation in recent years, guided by principles of sustainability and energy efficiency...The most recent investment is the new fabric steaming plant Nanomix Evo produced by Biella Shrunk Process, which stands out for its reduced steam consumption...

Iride srl consolidates the investment plan by purchasing a new Kinetika washing line

June 2024

Iride srl is a company founded in 2013 and operates in the field of fine fabrics dyeing and finishing, which has made an extensive program of investment in technological innovation in recent years, guided by principles of sustainability and energy efficiency...The wide range of fabrics treated by Iride srl. (cottons, linens, wool blends, polyamides and other synthetic fibers) has highlighted the versatility of the Kinetika system, as well as the improved washing effect...

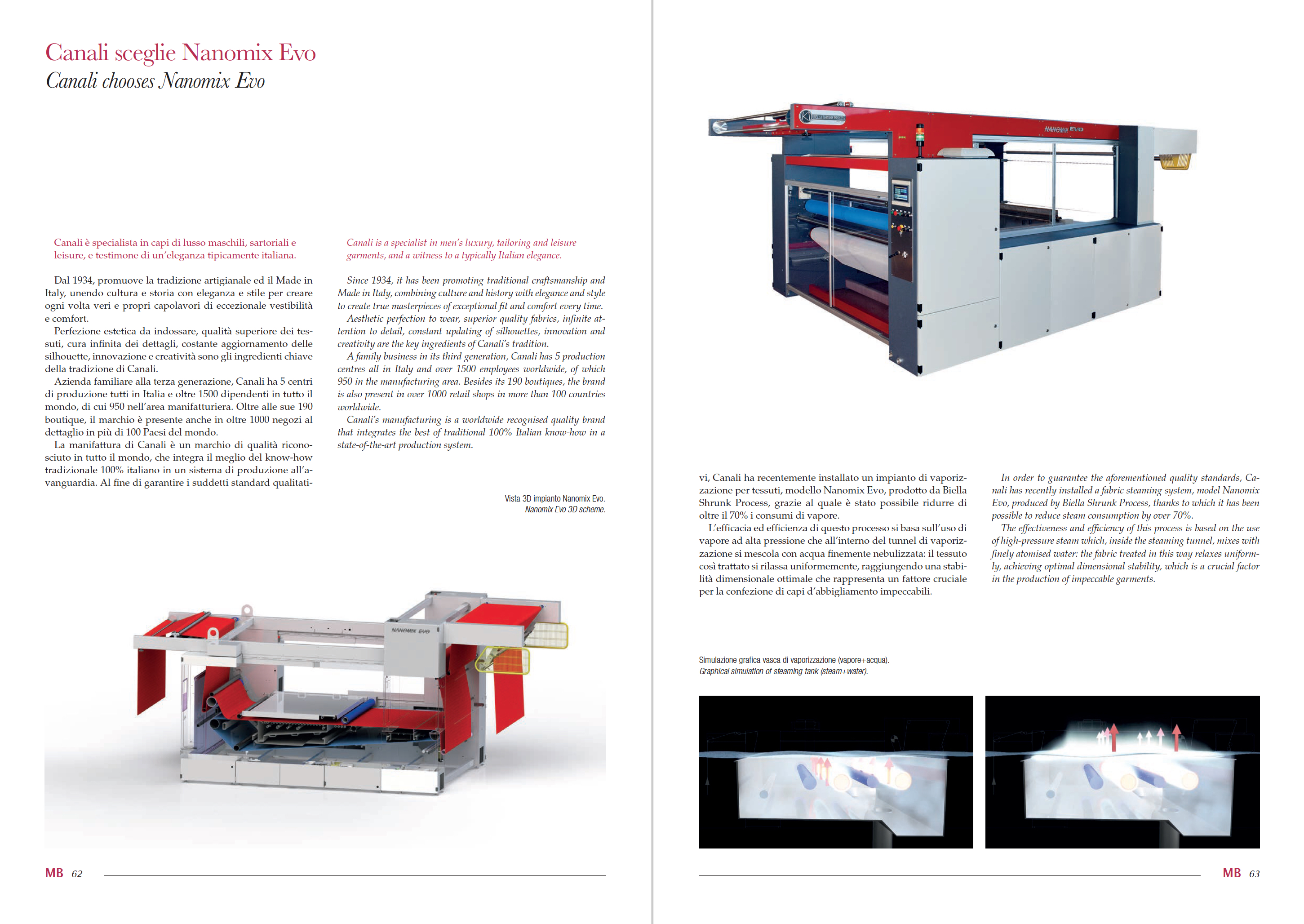

Canali chooses

Nanomix Evo

June 2024

Canali is a specialist in men’s luxury, tailoring and leisure garments, and a witness to a typically Italian elegance...has recently installed a fabric steaming system, model Nanomix Evo, produced by Biella Shrunk Process, thanks to which it has been possible to reduce steam consumption by over 70%.

Drago Lanificio in Biella, confirms the choice with Nanomix Evo

December 2024

Drago Spa is a well-established industrial group that occupies a leading position on the international textile scene...confirms that the new system has reduced steam consumption by around 30% and that thanks to the newly designed steaming tunnel, the results on the fabric have further improved, guaranteeing even more opaque and tridimensional effects.

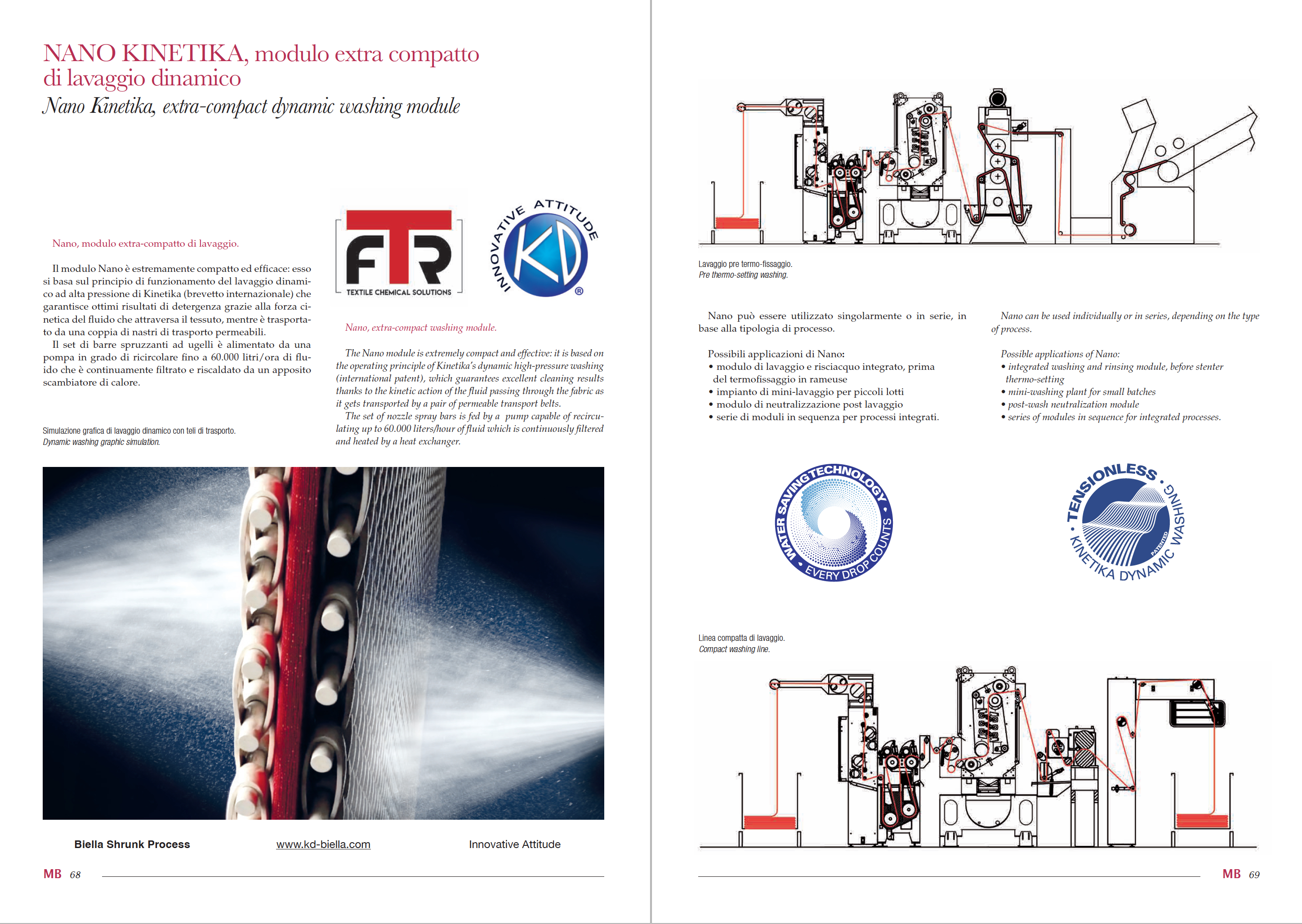

Nano Kinetika, extra-compact dynamic washing module

June 2025

The Nano module is extremely compact and effective: it is based on the operating principle of Kinetika’s dynamic high-pressure washing (international patent), which guarantees excellent cleaning results...The collaboration between FTR srl and Biella Shrunk Process has resulted in a new washing solution for fabrics that in many cas- es can be considered an alternative to dry cleaning...

MagnoLab and Biella Shrunk Process: real research and real innovation for sustainable solutions

December 2025

MagnoLab is the network of companies in the textile supply chain that was created to develop real solutions for the industry, create value and collaborate on current and future needs...Biella Shrunk Process took up this challenging invitation, proposing a brand-new machine under development in its own research center...he goal of the “Boosty” line, this is the name of the experimental ma- chinery, is in fact to propose an efficient and more productive alternative to the state of the art represented by finishing processes characterized by high consumption of water and steam...

Botto Giuseppe e Biella Shrunk Process, una partnership Botto Giuseppe and Biella Shrunk Process, a partnership dedicated to sustainability and innovation

January 2026

Botto Giuseppe e Figli S.p.A. has been producing fine yarns and fabrics since 1876. Today, the fourth generation of the family runs an international business with many of the world’s most prestigious luxury customers...invest in a new Kinetika fabric washing plant is consistent...The decision to invest in the Kinetika washing line is based on a vision linked to process optimisation, energy sav- ing and water saving...

* Courtesy of Made in Biella magazine